XADO is the only technology in the world which adds both weight and dimension to worn parts and completely restores their geometry while operating. The essence of XADO technology is the discovery of the process REVITALIZATION which changed the ordinary approach to repair and gave new opportunities in operation of machines and different mechanisms.

What is revitalization?

The term "Revitalization" (from Latin "vita" = life) literally means "returning to life". The revitalization process is based on unique physicochemical processes which, under certain conditions, take place in the friction zone.

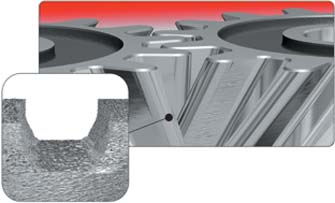

As soon as a mechanism begins to operate, it starts to wear out. Eventually, something will fail. Under load, the working surfaces of the parts rub, overheat and deform. Metal particles are simply taken away and wiped off the surface. Having lost weight and shape, the part cannot serve properly and fails.

XADO contains a building material and a unique energy activator which uses excess friction energy to create a new surface. It turns out that overloads, i.e. excessive energy which can ruin the inter-atomic bonds and damage the parts' surfaces can be "withdrawn" and even more - can be used for the growth of other matter!

How does wear usually occur?

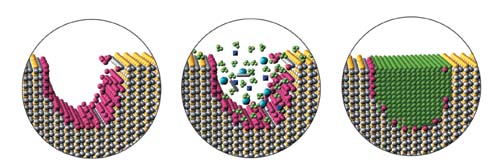

In the diagram form in the picture you can see some damage on one of the friction surfaces. In this case it is a scratch (in section) which occurred along the axis of move of the surfaces.

Attention! The marked area is the area of anomalous surface activity. The metal atoms have uncompensated double bonds: such atoms are very fragile and it is quite easy to separate or to tear them from the matrix.

Imagine a tree, which grows on the edge of the ravine. Under the effect of water and wind the soil gradually spoils, baring the roots. The tree is no longer firm in the ground and strong gust is enough to root it out of the soil.

The same process but much simplified occurs by the surface wear. The atoms easily tear off and the destruction progresses. Moreover, under the effect of overloading the whole set of atoms – clusters - can tear off. The catastrophic wear takes place.

So it was – until the discovery of the REVITALIZATION phenomenon, when the scientists discovered, that there is a possibility to stop the wear process and restore the wear surface! It turned out that it is really possible to create such conditions under which the part gains weight and size, restores its original form.

To create such useful conditions, it is necessary to add a specially synthesized substance – revitalizant XADO (2) in the friction zone. It contains the building material for the future surface and unique energy activator, which helps to transfer the excess friction energy for the creation of the new crystal lattice – new surface.

Where does revitalization begin?

How does the surface build-up occur?

Where does revitalization begin?

How does the surface build-up occur?

Revitalization begins in the places of the extreme wear, because there is enough excess energy for the beginning of the new process there and metal atoms have the largest number of free (uncompensated) bonds (1). These bonds like magnets seize and hold the building material – revitalizant (2) exactly in the places of wear. During the loading the energy activator directs the excess energy to the construction of the new crystal lattice. In such a way, a new coating (3) is created on the old base. In several minutes after the beginning of the revitalization a ceramic-metal patch (3) appears on the scratch place. The marked area, the area of anomalous activity, has disappeared. The energy processes have stabilized, the surface buildup has stopped. The mutual diffusion of two substances (metal and ceramic) and formation of the new coating are finished. Finally the defect is repaired. With all this going on, the new coating became much stronger.

What does revitalization give?

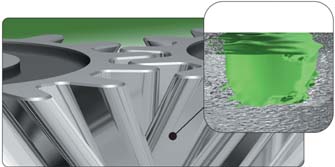

First, a new coating is formed on friction couple surfaces: the part increases in size getting back those “one-hundredths” and “one-tenths”, lost previously, “gone” into oil during operation. This means REPAIR.

Second, the coating obtained has unique characteristics: extreme hardness, high corrosion resistance and low surface roughness. Therefore, it is guaranteed that revitalized part will serve 2 – 4 times longer. This means WEAR PROTECTION. The conclusion is obvious: due to revitalization, you get a reconditioned part, which, as to its performance, is superior to a new one.

How is the surface buildup controlled?

Let’s have a look at the part in the microscope. Even a very smooth surface looks uneven at considerable magnification, looking like a chain of “peaks” and “cavities”. Little by little the wear seizes weak places, ”knocking” and “washing out” metal atoms, taking away them to the boring. The”cavities” become deeper and deeper. So, the 100% wear occurs not when the part turns into dust as some people mistakenly think, but when the “peaks” start wearing down. As long as the “peaks”, which remember the original size of the part, exist, the part can still be restored by subjecting to revitalization. It follows that the part will never gain in seize more than it should be. As soon as a peak and a cavity match, the energy conditions necessary for revitalization disappear. The system becomes stabilize. And the building material, which is left unused, will come into reaction as soon as the surface gives it warning of appearing of the area of anomalous surface activity (wear).

How big can the buildup be?

The consumer uniqueness of XADO revitalizants is that these are not imaginary atomic layers but actual microns in the pump element, "one-hundredths" in the engine, and "one-tenths" in the gearbox wheels.